Gravity-driven carton flow rail conveyor systems utilise nylon rollers to provide a smooth and efficient flow of cartons or boxes within a warehouse or distribution centre. These conveyor systems are designed to operate based on the force of gravity, allowing cartons to move from higher elevations to lower ones without external power sources.

The carton flow rail conveyor consists of inclined lanes strategically spaced along the tracks to create a gradual decline, which enables cartons or boxes to move along the conveyor under their weight.

The nylon rollers are chosen for their low friction properties, ensuring smooth movement and reducing the effort required to push or pull the cartons along the conveyor. This helps minimise the strain on workers and enhances the system's overall efficiency.

Features of Carton Flow Rail:

Specifications for Flow Rail:

| Frame Width: | 36mm |

| Overall Height: | 36mm |

| Length: | 3 metres |

| Order Code: | FRR002 |

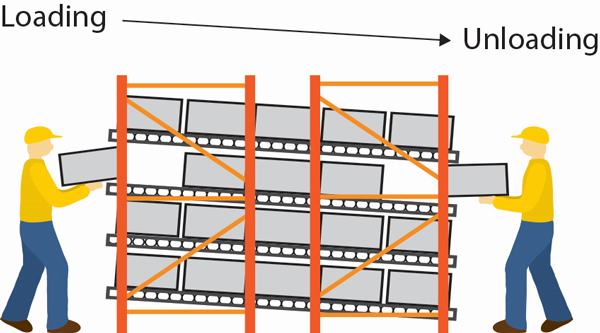

Gravity-driven carton flow rail conveyor systems are commonly used in order-picking areas or storage locations where a high volume of products needs to be handled. They enable easy access to products and promote first-in, first-out (FIFO) inventory management, as new cartons are loaded at the higher end of the conveyor and move towards the lower end for picking or distribution.

These conveyor systems are versatile and can be integrated into existing warehouse infrastructure. They offer benefits such as increased throughput, improved order accuracy, and reduced labour requirements, making them a popular choice for optimising material handling processes in many industries.