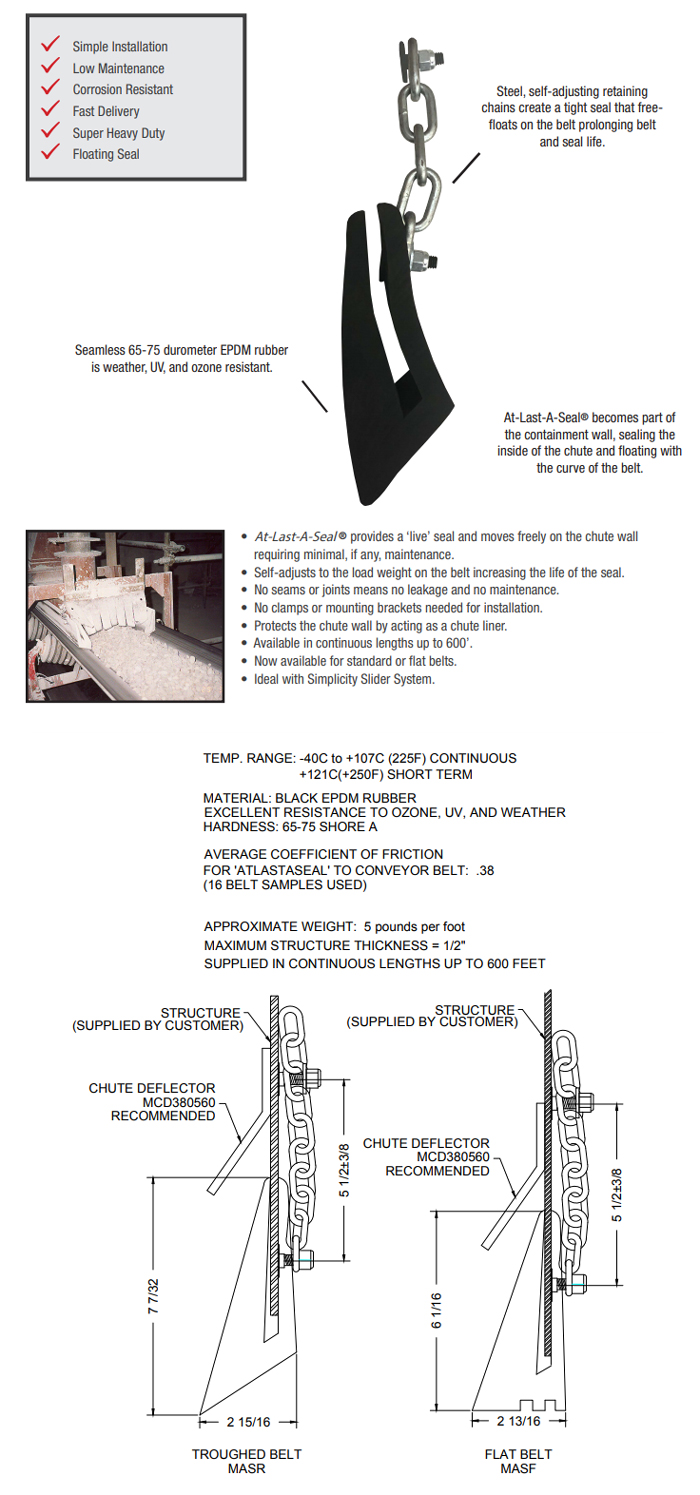

At-Last-A-Seal Skirtboard Seal for Sealing Transfer Points on Conveyor Belts. At-Last-A-Seal off a Low Maintenance, Corrosion Resistant, Super Heavy-Duty, Floating Seal becomes part of the chute wall and floats on the belt.

When the belt is loaded, the material presses down on the inside slope of the At-Last-A-Seal, and the pressure creates the seal without excessive drag and friction. As the belt load decreases and eventually empties, the pressure decreases so as not to wear the seal prematurely.

At-Last-A-Seal Skirtboard Seal is supplied in a continuous, seamless length to match your needs. There are no joints or seams that can leak or need additional maintenance. It also serves as a wear liner by encapsulating the lower portion of the chute wall.

Features of At-Last-A-Seal Skirtboard Seal:

We refer you to the Arch Environmental Equipment, Inc. website for full details regarding the Gordon At-Last-A-Seal Conveyor Sealing System and all Conveyor Accessories available.

There are many applications for At-Last-A-Seal, particularly in the mining and iron industry, in which continuous conveyor belts are utilised to move bulk materials such as coal, grain, and the like from one location to another. In any system, the bulk material must be deposited on the moving conveyor belt; interruption of belt movement to receive a new load is economically unfeasible.

At the discharge end, scraping or cleaning the belt is usually necessary to ensure all of the bulk material is left at the desired new location. Both ends of such a continuous belt conveyor system present substantial problems; this invention is concerned with the problems and difficulties in depositing bulk material on the moving belt for transport to a distant location.

A major problem of the input station of any continuous conveyor belt system is leakage of the bulk material transported by the system. Broadly speaking, this has been met to a substantial extent by resilient aprons affixed to rigid skirtboards around the input station. Examples of previously known resilient skirtboard aprons and apron mounts are disclosed in Gordon U.S. Pat. Nos. 4,231,471, 4,436,446, 4,877,125, and 4,989,727.

Perhaps the best skirtboard apron is the simple but effective device described and claimed in Gordon U.S. Pat. No. 4,989,727 and sold commercially under the designation At-Last-A-Seal. Even that skirtboard apron, however, may have leakage problems, particularly due to the appreciable movement of the conveyor belt, vertically or laterally, other than in the conveying direction through the input station.

Accordingly, the invention relates to an input station for a belt conveyor comprising a continuous conveyor belt of given width having a conveyor run extending through an input station to and around a head pulley at a discharge location and a return run from the head pulley to and around a tail pulley back into the input station.

The input station comprises a frame, centre belt support means having a width less than the belt width, mounted on the frame, for supporting the central portion of the conveyor belt throughout the input station; the centre belt support means comprises a plurality of support rollers extending across and engaging the underside of the conveyor run of the conveyor belt throughout the input station.

The input station further comprises first and second lateral belt support means, each having a width less than the belt width, mounted on opposite sides of the frame adjacent to the centre belt support means; each lateral belt support means includes at least one belt support rail, extending parallel to the conveyor belt, engaging the underside of the conveyor run of the conveyor belt and supporting a lateral portion of the conveyor belt, with no appreciable sag, throughout the input station, at an acute angle to the central portion of the conveyor belt. The input station also has first and second input skirtboard means positioned above opposite sides of the conveyor belt, each extending longitudinally of the belt, for sealing off the lateral edges of the conveyor belt at the input station.

Priced on application - Please get in touch with our office for a quote.